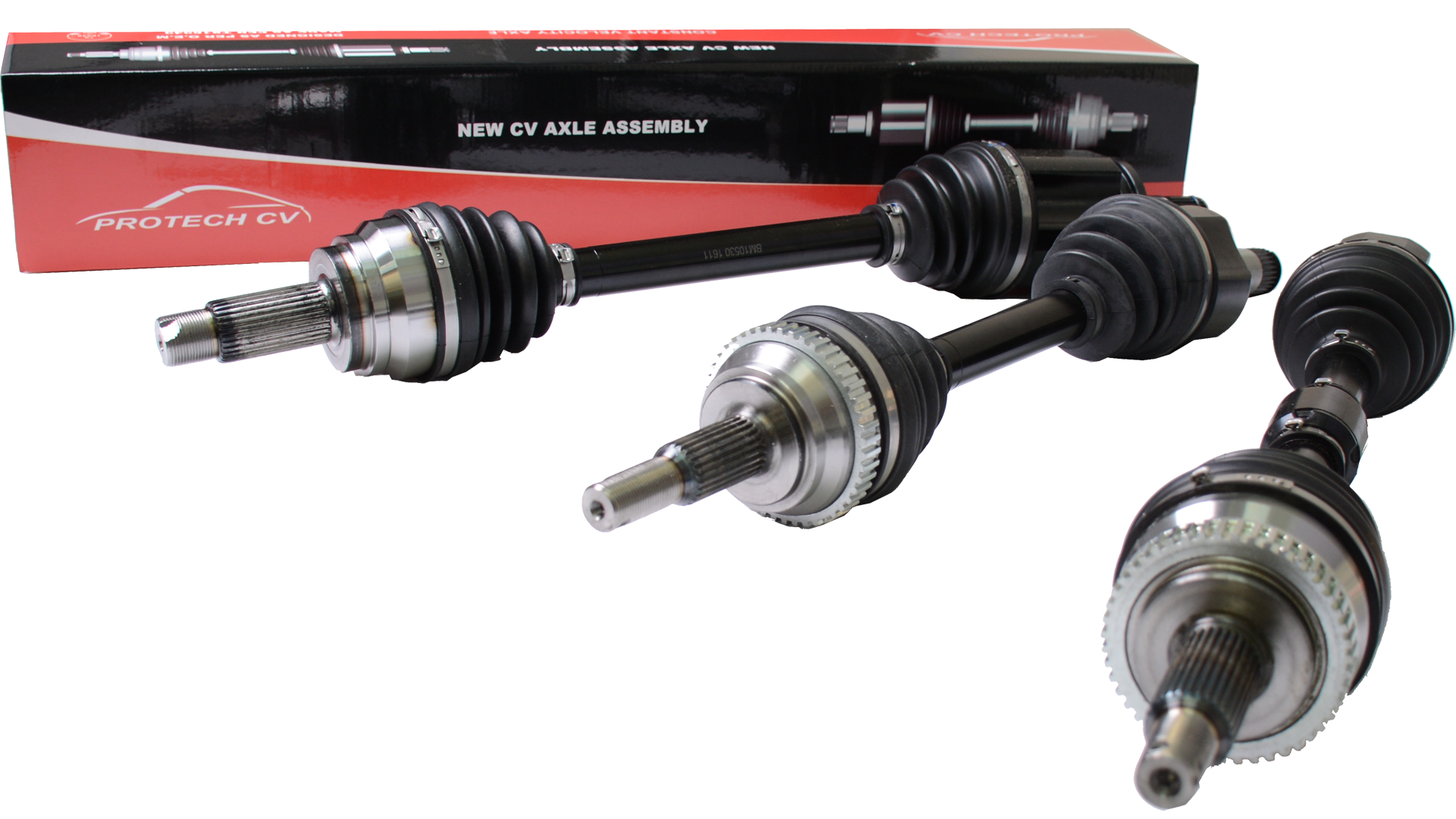

Drive Shaft Assembly

Features:

• Full range of external CV joint OE forged parts, integrally forged, complete metal flow lines, excellent metallographic structure, higher quality, stronger performance

• Precision grinding of star wheel and CV joint grooves, double arc point contact, more durable use, more stable and outstanding performance

• Uses high-quality steel and OE processes and accessory suppliers, stable quality

• Automation level brings more efficient processing efficiency and high-quality processing accuracy

• Made with high-quality 55# and 40Cr steel from major manufacturers, ensuring better quality

• Full range of ball cages are OE precision forged parts, integrally forged, processed through annealing, shot blasting, cold finishing, and other procedures, meeting OE standard metallography and metal flow lines, featuring stronger metal structure and torsion resistance

• Full range of external ball cage OE precision forged parts, integrally forged, complete metal flow lines, excellent metallographic structure, higher quality, stronger performance

• Precision grinding of the star wheel and ball cage grooves, double-arc point contact, more durable in use, with more stable and outstanding performance

• Uses high-quality steel and OE processes along with accessory suppliers, ensuring stable quality.

• Automation level brings higher processing efficiency and superior processing precision

• OE-quality precision forged inner and outer ball cages, finely ground outer ball cage

• AAR large swing angle inner ball cage design, maximum swing angle 26 degrees

• TPEE anti-assembly + OE clamp, resistant to high and low temperature grease, suitable for operating conditions from -30°C low temperature to 120°C high temperature

• 100% one-to-one matching of tripod and sliding sleeve to ensure assembly accuracy