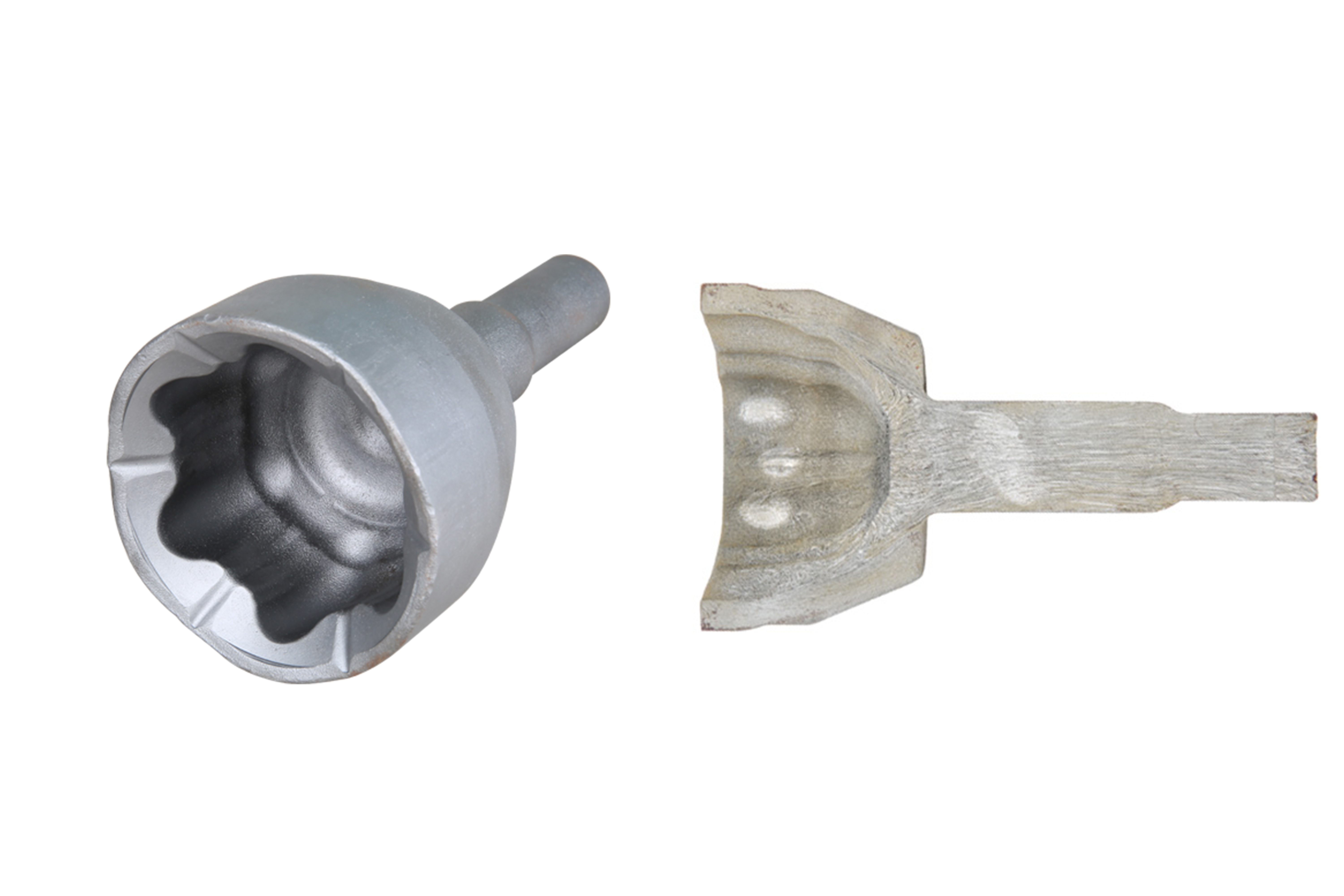

CV Joint

Product Category:

Product Introduction

• Using high-quality 55# and 40Cr steel from major manufacturers, ensuring better quality

• Full range of ball cages are OE forged parts, integrally forged, undergoing annealing, shot blasting, cold finishing and other processing steps, meeting OE standard metallography and metal flow lines, with stronger metal structure and torsion resistance

• Outer ball cage grooves are precisely ground, inner ball cage forks and cavities are 100% matched one-to-one, with better gap control

• Welded products use argon arc welding process, resulting in less deformation and higher strength

• Long-handle inner ball cage uses friction welding process, with friction allowance far exceeding OE standards, ensuring strength

• Using OE factory molybdenum disulfide lithium-based grease, resistant to high and low temperatures, suitable for various harsh road conditions and extreme weather

• Supporting accessories all use OE factory or high-quality major manufacturer products, ensuring stable and reliable quality

Product Inquiry

*Note: Please be sure to fill in the information accurately and keep communication smooth, we will contact you as soon as possible

Related Products